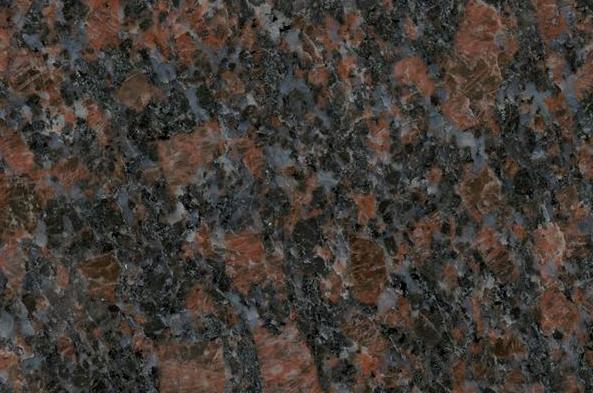

Tan Brown Granite (UK Brown Granite)

Overview

Tan Brown Granite, commonly referred to as UK Brown Granite, is a premium granite quarried in India. Characterized by its brown base with distinctive red mineral flecks, this stone is widely used for both interior and exterior wall cladding, flooring, and decorative elements. Available in color variations including deep red, light red, large fleck patterns, and small fleck patterns, it offers consistent veining and stable coloration with a naturally polished luster. While its high hardness ensures durability, this property also makes it challenging to work with and repair if fractured. In the Chinese market, the brown base with small mineral flecks is particularly favored.

Common Applications

- Slabs & Thin Slabs

- Engineering Panels

- Flooring Tiles

- Columns & Hollow Columns

- Roman Columns

- Countertops (Vanity Tops, Table Surfaces)

- Wash Basins & Sinks

- Architectural Moldings

- Door Framing

- Window Sills

- Custom Stonework

- Stone Curtain Walls

- Mosaic Inlays

- Standard Dimension Stones

Technical Specifications & Quality Considerations

Advantages

- Stable geological composition with minor natural variations

- Uniform patterning and color consistency

- High-gloss natural polish

- Exceptional structural integrity

- Large quarry blocks (minimizing waste)

Quality Variations

- Common natural imperfections:

- Black mineral inclusions (“black flecks”)

- Red veining (“blood veins”)

- Inconsistent patterning

- Micro-fractures

- Color/texture may vary slightly between quarry batches

Quality Control Protocols

1. Angular Precision Testing

- Tool: 90° steel square (0.13mm tolerance, 500×400mm)

- Method:

- For slabs ≤500mm: Measure diagonal angles

- For slabs >500mm: Test all four corners

- Measure gap between square and slab edge using feeler gauge/caliper

- Tolerance: Max. measured gap ≤0.1mm

2. Visual Inspection Standards

- Color Consistency: Compare sample to batch at 1.5m distance

- Surface Defects:

- Tool marks: Visible at 1.5m viewing distance

- Vein counting: Visual tally of colored streaks

- Chips/Fractures: Measure with digital calipers

- Step defects: Caliper-measured height ≤0.2mm

- Cracks: Auditory test (metallic hammer tap for hollow sounds)

- Staining: Measure spot dimensions and count occurrences

Material Hardness & Durability

Rated 6-7 on Mohs Scale (comparable to feldspar/quartz):

- Talc | 2. Gypsum | 3. Calcite (marble) | 4. Fluorite

- Apatite | 6. Feldspar (granite) | 7. Quartz (granite)

- Topaz | 9. Corundum | 10. Diamond

Implications:

- Superior abrasion resistance vs. common debris (sand rates 3-7 Mohs)

- Requires diamond tools for fabrication

- Resists scratching from most urban pollutants

- Maintains structural integrity in high-traffic applications

Maintenance Notes

- Avoid calcium-dissolving chemicals (pH-sensitive)

- Regular sealing recommended for exterior use

- Use non-abrasive cleaners to preserve surface finish

This technical profile provides essential information for architects, contractors, and stone fabricators considering Tan Brown Granite for premium construction projects.

This version maintains technical accuracy while using international stone industry terminology. It’s structured for easy scanning with clear headers and bullet points, ideal for B2B audiences. Would you like me to optimize any specific section further?

China Natural Stone Manufacturer, Supplier, Wholesaler and Exporter

China Natural Stone Manufacturer, Supplier, Wholesaler and Exporter