As cinco precauções para a construção de escadas de mármore

As escadas são um componente importante do espaço de conexão, e também uma paisagem do design da casa. Como um meio de transporte vertical, Eles conectam de perto os pisos. No entanto, Além de cumprir funções práticas, Eles também devem ser projetados como uma obra de arte.

Os materiais usados para decorar as escadas também são muito diversos. Mármore natural, que por si só tem um sentimento artístico, tornou -se uma grande opção para projetar escadas.

Que detalhes devemos prestar atenção a?

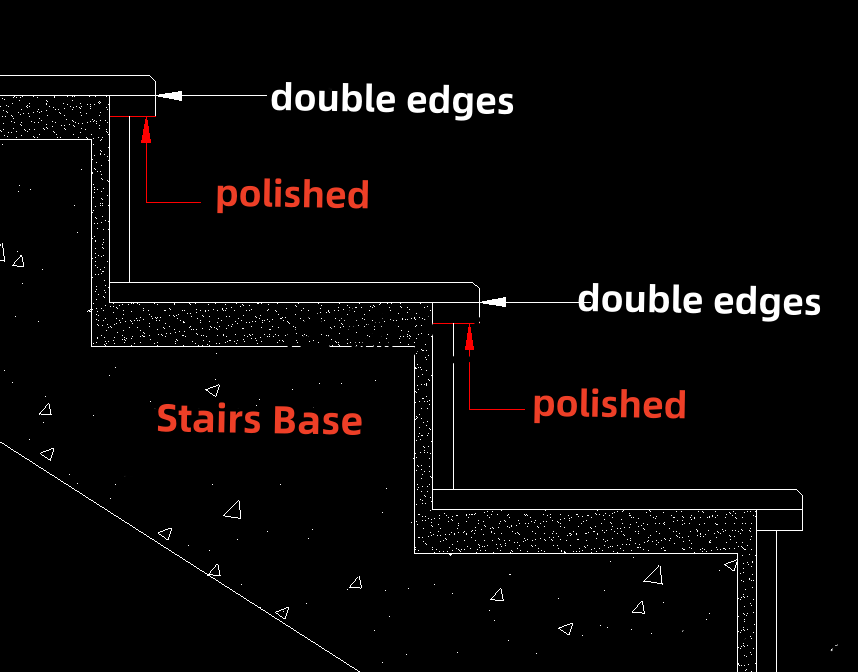

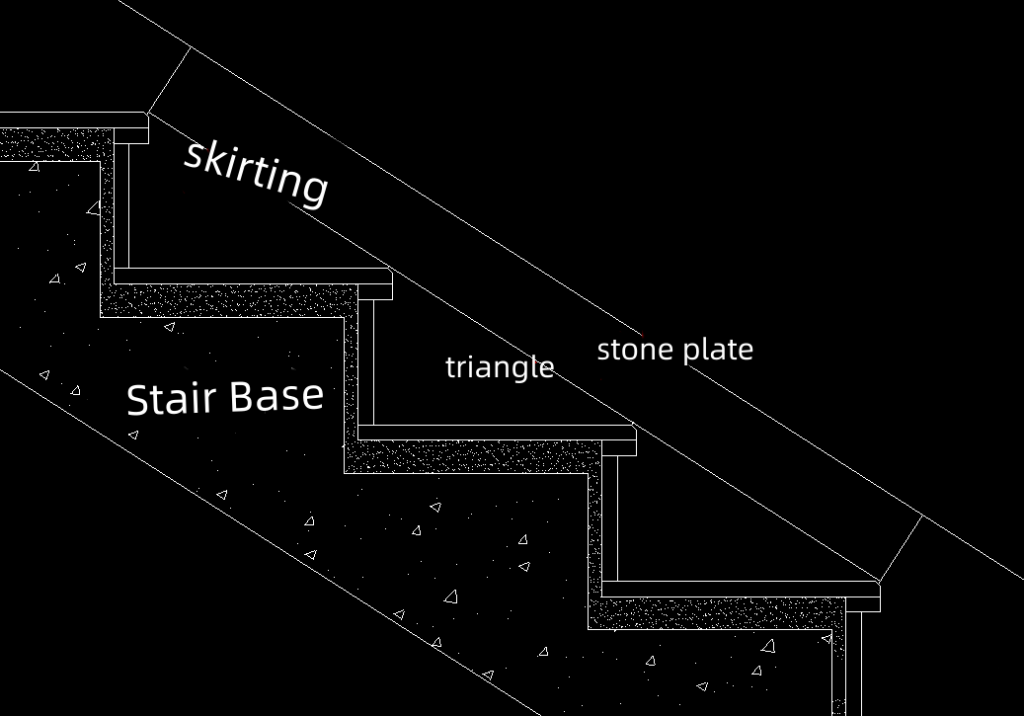

Primeiro, Os dois lados do piso da escada estão espessados e a borda inferior também deve ser polida. não apenas polir as bordas duplas.

Este é um detalhe de processamento. A seção e a parte traseira da própria pedra não são brilhantes. A parte inferior das duas bordas pode ser vista em algumas posições da escada. A superfície lisa é feita no fundo das duas bordas da superfície da etapa para beleza e conveniência da limpeza.

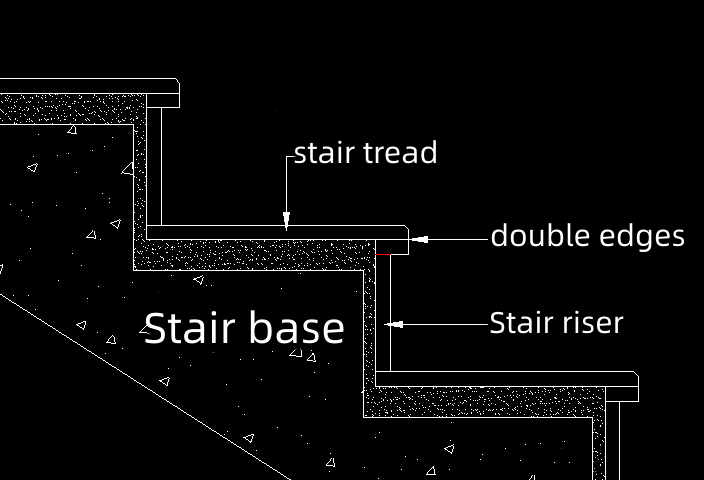

Segundo, a pressão das bordas duplas acima da pedra riser.

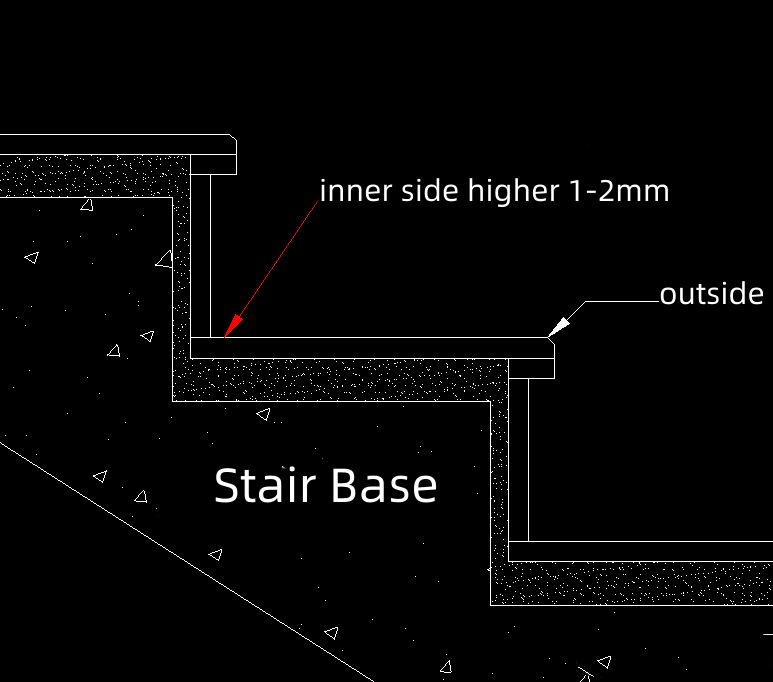

Terceiro, Lado interno da escada de piso mais alto 1-2mm que o exterior do piso de escada.

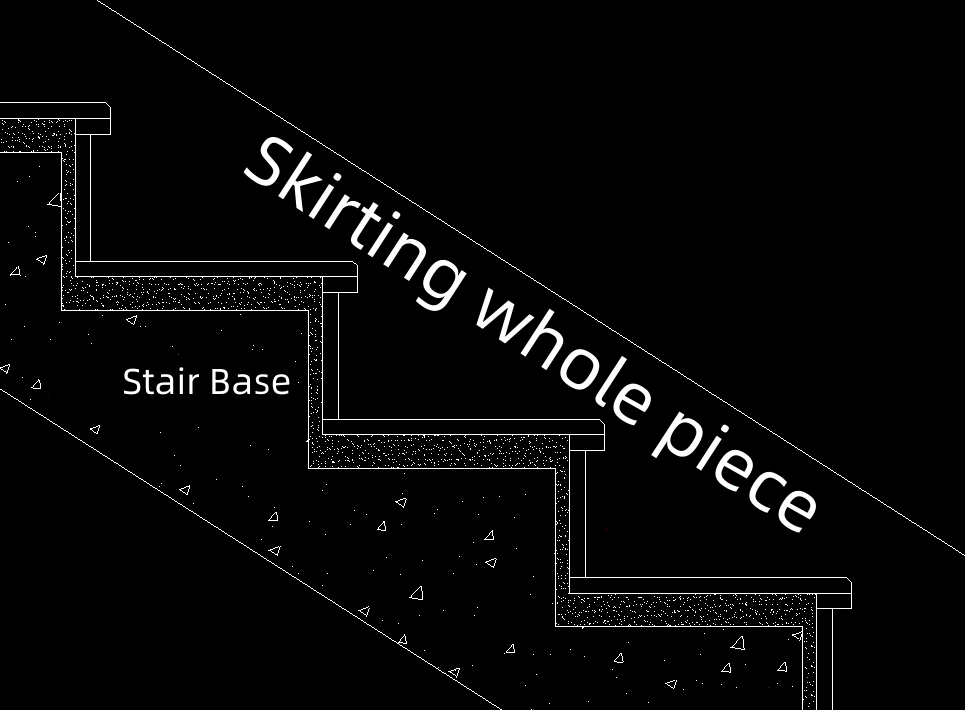

Quarto, No interior da linha de rodapé ou trilho de vidro, Faça um prato cortado a tamanho para rodapé ou grama de grama no local.

Comparado com o jeito antigo, Dessa forma, pode efetivamente reduzir a costura na linha de rodapé ou no lado interno do trilho de vidro, Torne a superfície da placa completa e o grão completo, e pode aumentar com mais eficácia a beleza das escadas. A desvantagem desse método é que a taxa de desperdício de materiais é relativamente mais.

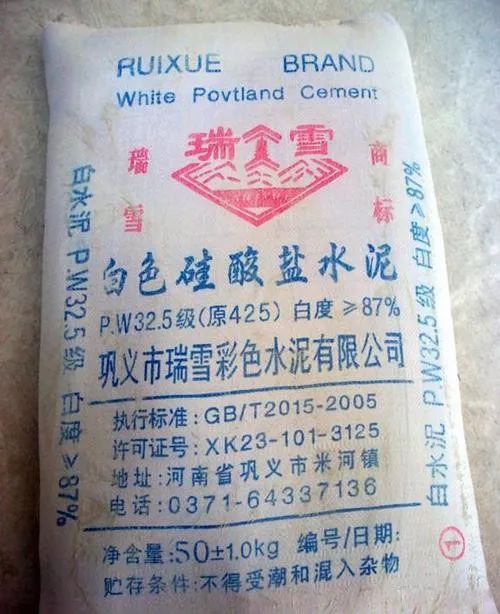

Quinto, Quando mármore de cor clara é usada como escada, cimento branco (Cimento de Portland branco) deve ser usado para pavimentação.

O próprio mármore natural tende a alcalina, e o uso de pavimentação de cimento branco pode reduzir efetivamente a ocorrência de reação alcalin. O mármore natural em si tem muitas lacunas de grãos e é pavimentado com cimento branco. Mesmo que o cimento penetra nas lacunas da pedra, não afetará a beleza.

Fabricante de Pedra Natural da China, Fornecedor, Atacadista e Exportador

Fabricante de Pedra Natural da China, Fornecedor, Atacadista e Exportador