The Five Precautions for Marble Stairs Construction

Stairs are an important component of connecting space, and also a landscape of home design. As a means of vertical transportation, they closely connect floors. しかし, in addition to meeting practical functions, they should also be designed as a work of art.

The materials used to decorate the stairs are also very diverse. 天然大理石, which itself has an artistic feeling, has become a major choice for designing stairs.

What details should we pay attention to?

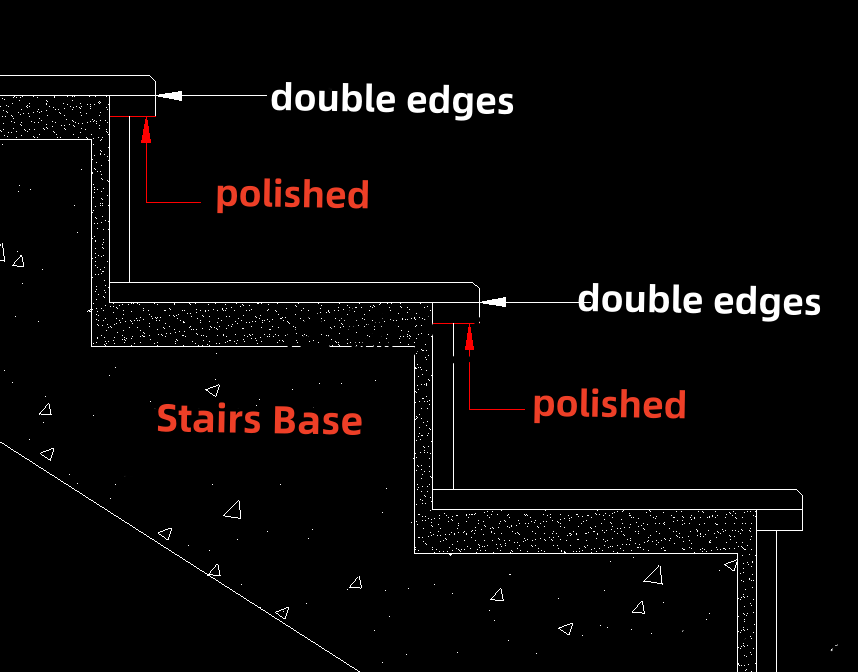

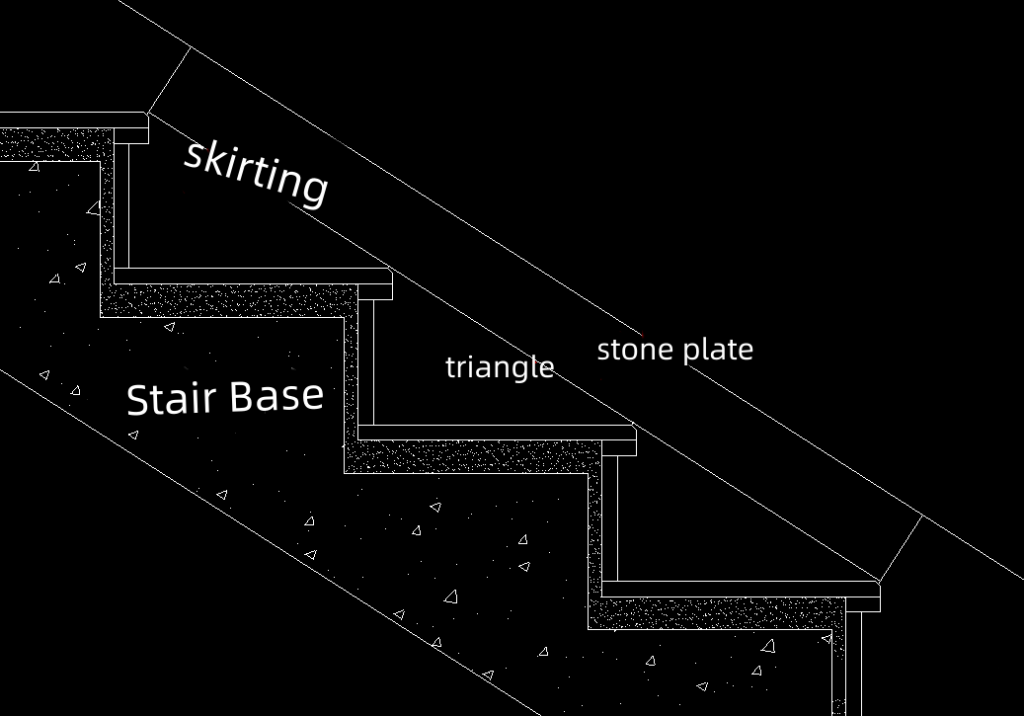

初め, the two sides of the stair tread are thickened and the lower edge shall also be polished. not just polish the double edges.

This is a processing detail. The section and backside of the stone itself are not shiny. The lower part of the two edges can be seen at some positions of the stairs. The smooth surface is made at the bottom of both edges of the step surface for beauty and convenience of cleaning.

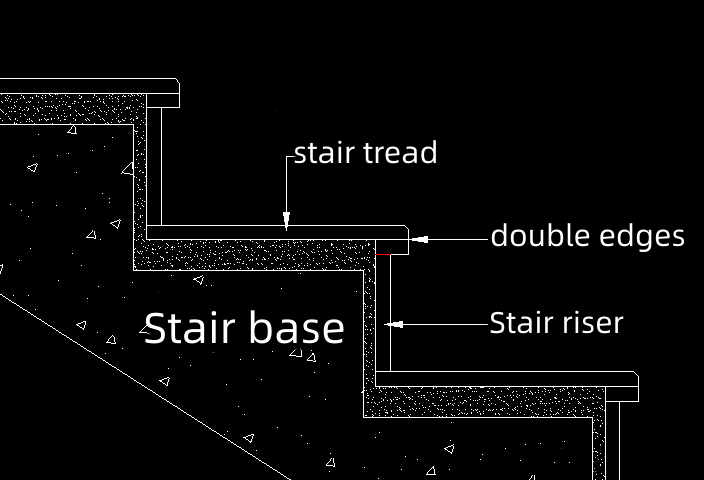

Second, the double edges pressure on above the riser stone.

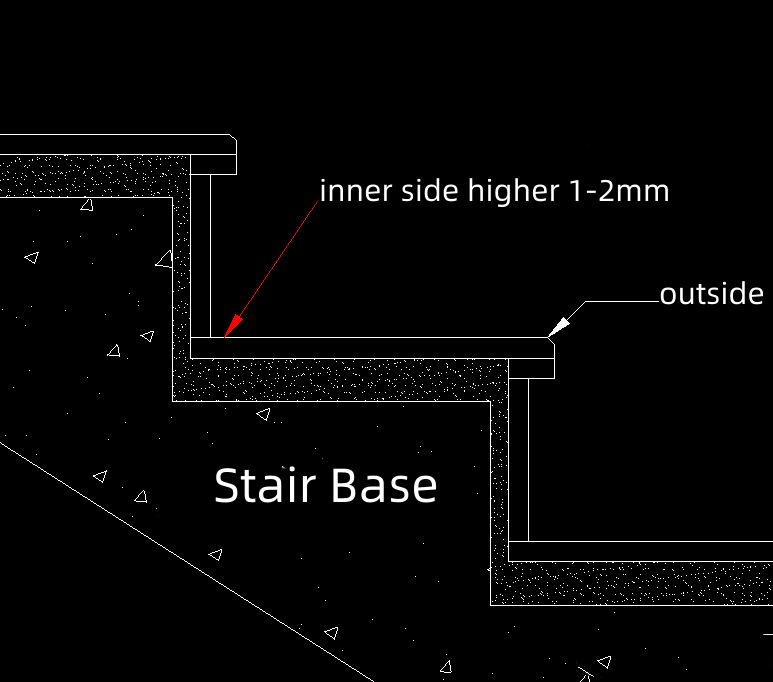

Third, Inner side of Stair tread higher 1-2mm than the outside of stair tread.

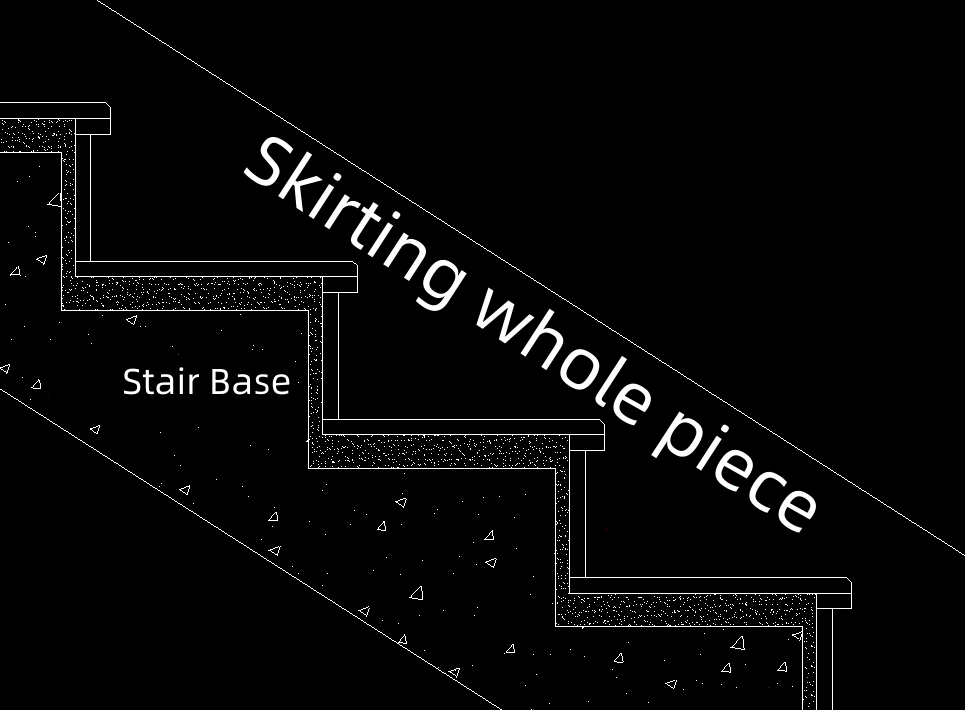

Fourth, On the inside of the skirting line or glass railing, make cut-to-size plate for skirting or grass railing on site.

Compared with the old way, this way can effectively reduce the stitching on the skirting line or the inner side of the glass railing, make the board surface complete and the grain complete, and can more effectively increase the beauty of the stairs. The disadvantage of this method is that materials wastage rate is relatively more.

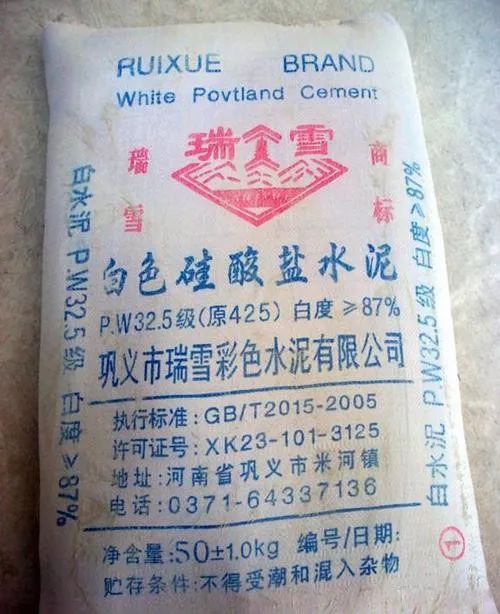

Fifth, when light color marble is used as stairs, white cement (white Portland cement) shall be used for paving.

The natural marble itself tends to alkaline, and the use of white cement paving can effectively reduce the occurrence of alkali reaction. The natural marble itself has many grain gaps and is paved with white cement. Even if the cement penetrates from the gaps of the stone, it will not affect the beauty.

中国天然石メーカー, サプライヤー, 卸売業者および輸出業者

中国天然石メーカー, サプライヤー, 卸売業者および輸出業者